Fretwork and Piercing

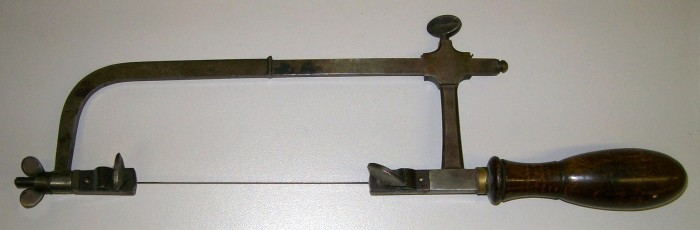

Fretwork is the cutting of intricate designs into wood, metal and other materials using a fretsaw. Fretsaws have a deep frame to allow for more mobility and less restriction when cutting into wider areas of material. The fine-toothed blade is short in comparison to the frame, which not only allows it to retain some strength, but also gives it more mobility and precision when working closer to the material for intricate work.

This process often started with a piece of sheet metal on which a design would be drawn or stenciled by hand. Where required, a centre punch was used to make slight impressions in the metal to prevent the drill bit from slipping. A hand drill could then make initial holes in specific areas, just large enough to allow the partially attached fine blade of the fretsaw to be threaded though and then reattached to the other side of the fretsaw frame. The blade itself was then lubricated, often with beeswax, and the cutting process could begin. The fretsaw is able to cut at very precise angles as well as tight radii, curves and cornering. If needed, edges could then be perfected or enhanced using fine hand files.

Piercing is the method of cutting material from areas of an object for intended purpose or decoration. Traditionally used by jewellers, the blades of a piercing saw are even finer than those of a fretsaw and are capable of cutting to a higher level of precision, ideal for the most delicate design and detailing. The piercing saw is similar in appearance to a fretsaw, but has a shallower frame due to its intended use on smaller areas of metal. The process of cutting with a piercing saw is almost identical to that of a fretsaw.

The fretwork process was often used to cut out brass design, detailing, monograms, crests etc to be inlaid into boxes, whilst the piercing process was more related to the silver or silver-plated contents of a dressing case.

Antique fretsaw.

Antique piercing saw.

Fretworked brass inlay on an antique rosewood jewellery box.

Close-up of a pierced silver dressing case jar lid by George Betjemann & Sons.

Fretworked brass inlay on an antique jewellery box in coromandel.

Price On Application

Price On Application